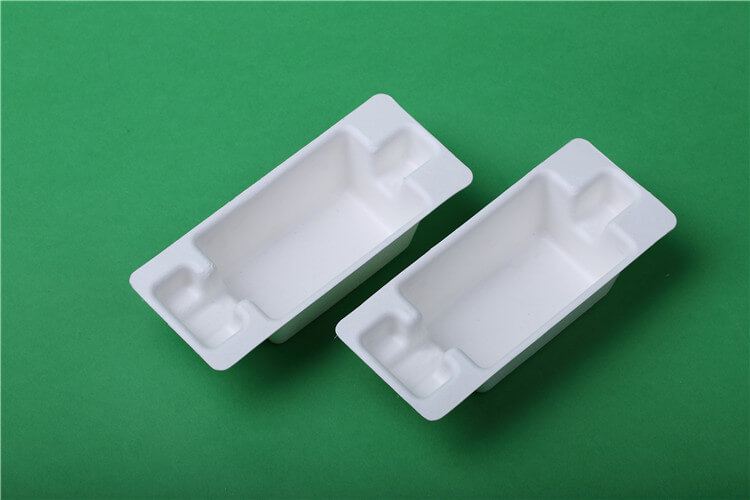

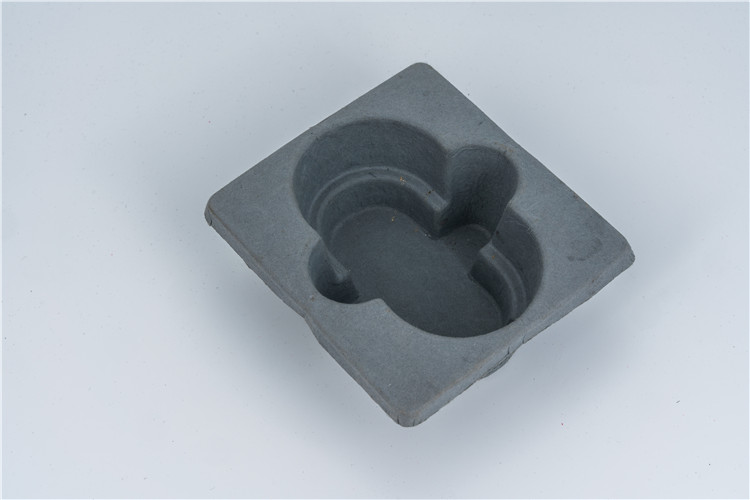

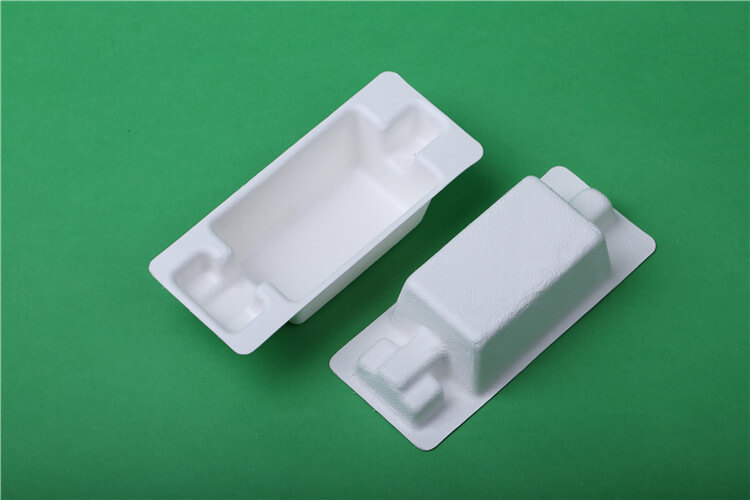

Molded Pulp Specifications

| Specification | Wet Pressing Molded Pulp | Dry Pressing Molded Pulp |

|---|---|---|

| Model Number | BNT-EC030 | N/A |

| Material | Sugarcane fiber | Corrugated pulp, wood pulp |

| Color | White | Natural, Black, White |

| MOQ | 10000 pcs | N/A |

| Sample Mold Cost | 400~550 USD | N/A |

| Sample Lead Time | 7 days | N/A |

| Production Mold Lead Time | 10 days | N/A |

| Sustainability | Biodegradable & Compostable | Recyclable |

| Surface | One side smooth, another side with texture | Rough surface |

| Logo | Embossing, debossing, printed | Embossing, debossing, printing |

| Thickness | 0.7~1.2 mm | 1.5~3.0 mm |

| Performance | Great | Good |

| Cushioning | Great vibration & cushioning | Good vibration & cushioning |

| Protection | Geometry | Geometry |

| Shipping & Storage | Stackable, low shipping and storage cost | Stackable, high shipping & storage cost |

| Static | Static neutral | Static neutral |

| Climate Tolerance | Non-affected by extreme high & cold temperature | Humidity affects performance |