Design & customization

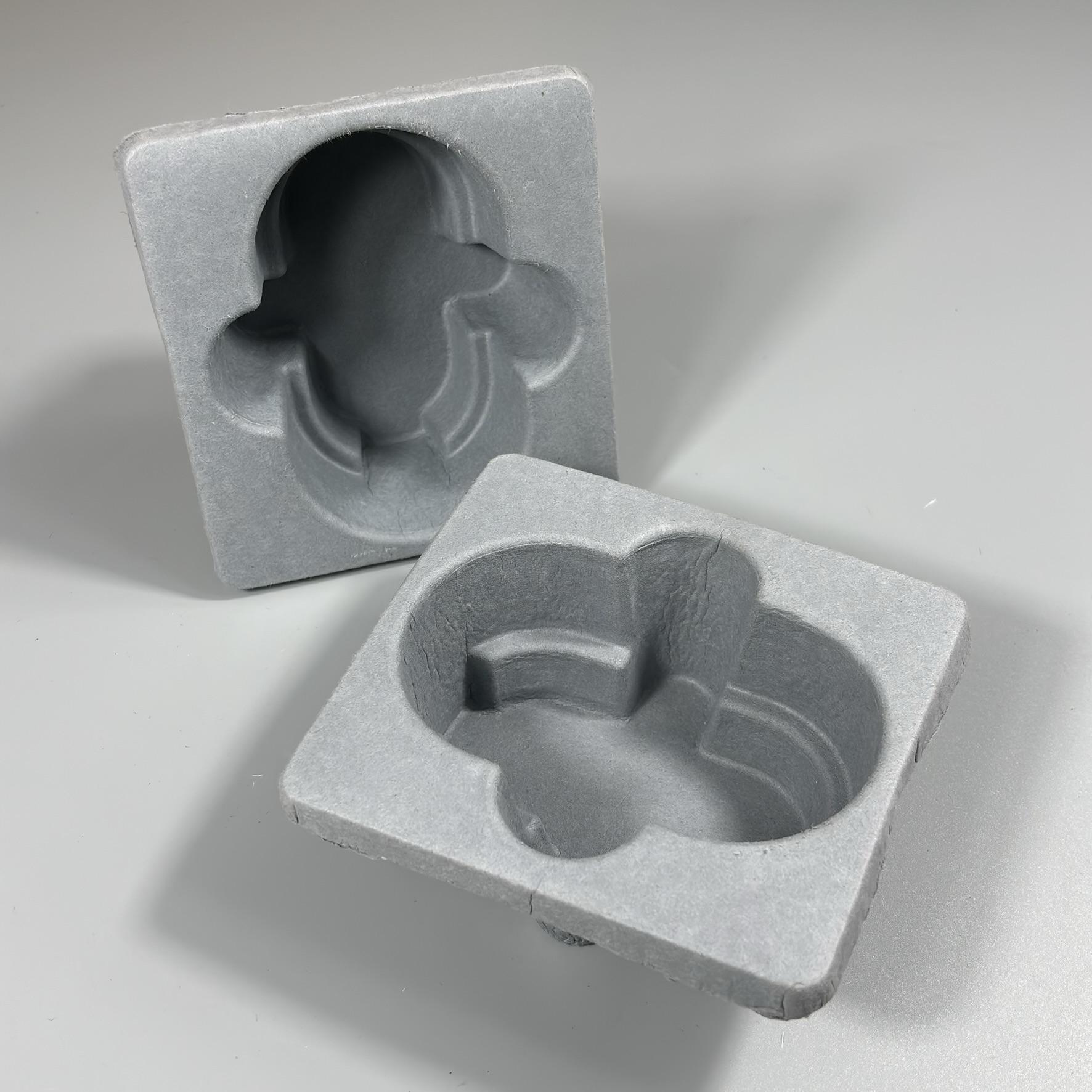

- Send CAD or product samples and we design a cavity layout to your exact device geometry.

- Options: finger‑notches for easy lift, cable channels, accessory pockets, clip posts, and multi‑layer kits (top device, bottom accessories).

- Keep a common outer footprint with interchangeable inner trays to cover multiple SKUs while using the same outer box.

Performance & testing

- Typical thickness 0.8–1.5 mm for electronics trays; reinforced ribs available for heavier components.

- Static‑neutral, low‑lint material suits sensitive electronics.

- We provide guidance for ISTA‑style drop, vibration and compression tests and tune geometry to pass target protocols.

Materials & sustainability

- Recycled paper and agricultural fibers (bagasse) form a mono‑material solution that simplifies recycling.

- Water‑based pigments enable grey, white, black or brand‑matched colors without plastic films.

- FSC options and sustainability data sheets available on request.

Sampling & lead time

- DFM review and layout proposal within a few days.

- Sample mold + samples: about 10 days.

- Mass production: typically 15–25 days after approval.

- MOQ: 5000 pcs per design/color.

Packing & delivery

- Trays nest tightly in master cartons; pallets optimized for export to reduce freight and emissions.

- Shipping terms EXW/FOB/CIF available with export documentation.

FAQs

Q1: Can you match our device shape exactly?

A: Yes. Provide CAD or physical samples and we’ll design precise cavities for a no‑rattle, scratch‑safe fit.

Q2: What colors are available?

A: Natural grey, white, black and any Pantone custom using water‑based pigments.

Q3: Are the trays waterproof?

A: Standard trays are fiber‑based; optional water‑resistant coating or liner can be added for high‑humidity routes.

Q4: What thickness should we choose?

A: 0.8–1.5 mm is common for electronics. We’ll recommend wall thickness and ribs based on weight and drop‑test needs.

Q5: Can we emboss our logo?

A: Absolutely. Embossed/debossed logos and functional pictograms (cable, charger, manual) can be molded into the tray.

Q6: Are they recyclable and compostable?

A: Yes. They are paper‑fiber based, recyclable in most paper streams and biodegradable/compostable under proper conditions.

Q7: What information do you need to start?

A: Device dimensions/CAD, carton size, desired layout, color and logo files, target quantity and timeline.

Ready to build a premium, plastic‑free electronics insert?

Share your specs and branding. We’ll design the cavity, sample fast and deliver on time with BonitoPak PM‑212.