Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

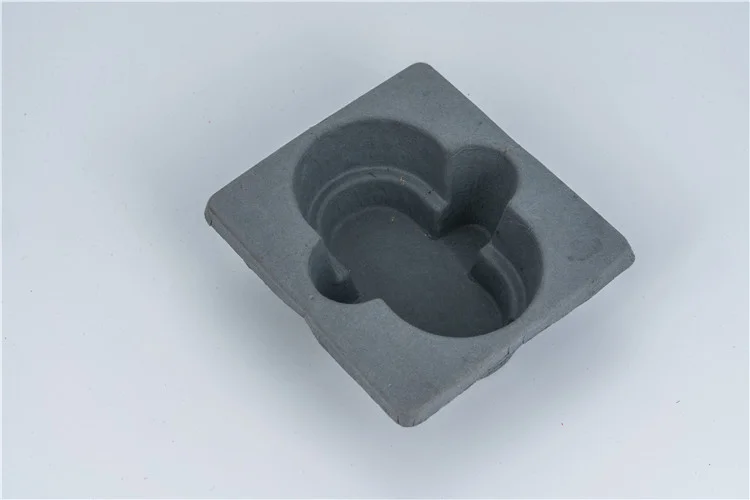

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

Design and customization

Performance and testing

Sustainability and materials

Production, quality and logistics

Typical applications

Q1: Can you match our exact bottle profile?

A: Yes. Provide CAD or a sample bottle and we’ll design a precise cavity with neck/shoulder support for a no‑rattle fit.

Q2: Is the tray suitable for e‑commerce shipping?

A: With the correct wall thickness and reinforcement ribs, trays perform well in drop and vibration tests. We’ll tune the geometry to your route and carton.

Q3: What colors are available?

A: Natural kraft and white are common. We can match Pantone colors to coordinate with your label or box design.

Q4: Can we add branding on the tray?

A: Embossed or debossed logos, icons and text are available. Printing typically goes on the outer box or sleeve.

Q5: Are these recyclable and biodegradable?

A: Yes. Made from plant fibers, the inserts are recyclable in most paper streams and biodegradable under appropriate conditions.

Q6: What is the MOQ and lead time?

A: MOQ 5000 pcs. Samples in about 10 days; production 15–25 days after approval.

Q7: Can the same insert fit different bottle shapes?

A: We recommend one insert per bottle profile for best protection. However, we can design flexible cavities for small variations within a SKU family.

Ready to elevate your wine packaging?

Share bottle dimensions or CAD, box size, color and logo. We’ll design the cavity, sample fast, and deliver on time with BonitoPak PM‑147.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Introduction: Why Home Plastic Injection Molding Is Becoming Popular Plastic injection molding has long been

Introduction: Why Wood Pulp Machinery Is Critical for the Industry For businesses involved in paper

Introduction: Why the Shift Away from Plastic Matters For decades, coffee machines have relied on