Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

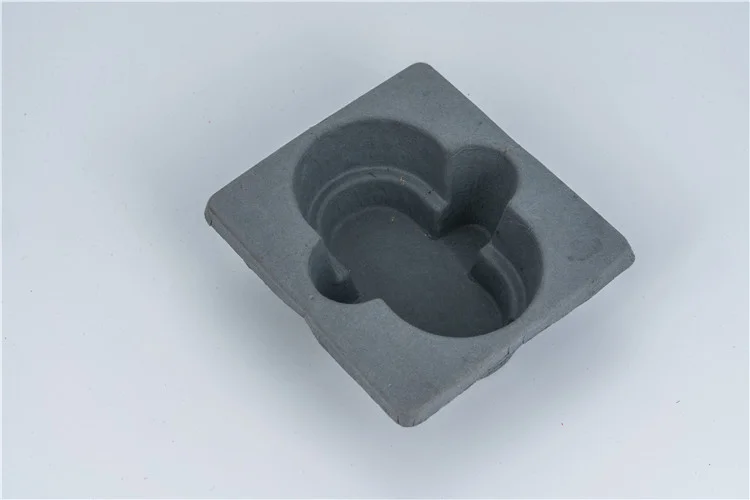

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

Great packaging should do more than hold products—it should work hard in transit, on shelf, and in customers’ hands. We start with cellulose‑rich fibers (recycled paper, sugarcane bagasse, or bamboo) and form them with wet‑press molding to achieve crisp geometry and consistent tolerances. The dense fiber structure cushions impacts and resists crush in stacks, while custom cavity design reduces movement that can crack eggs or scuff delicate goods. Choose standard counts (6/10/12/15/18/30) or create a layout for specialty sizes; add finger‑pulls for easy opening, ventilation for freshness, and label flats for barcodes or branding.

Your brand stays front and center. Embossed or debossed logos create tactile, premium detail without inks, and color matching keeps every touchpoint on‑brand. Operationally, the cartons and trays are lightweight and nestable, lowering pallet height and warehouse footprint—key wins for farms, distributors, and eCommerce. The single‑material, plastic‑free design is widely recyclable where fiber packaging is accepted and is designed to be biodegradable under proper conditions, helping you communicate a clear end‑of‑life message.

Need documentation for food contact or regional compliance? Share your requirements and we’ll advise the right specs for your market. With an MOQ of 5,000 pcs and full OEM/ODM support, you’ll prototype quickly, scale consistently, and deliver a packaging experience that feels responsible, reliable, and retail‑ready.

FAQs:

Q1: Can you make custom egg counts and sizes?

A: Yes. We produce standard 6/10/12/15/18/30 counts and fully custom sizes, cavity shapes, handles, and vents to fit your needs.

Q2: Are these trays recyclable and biodegradable?

A: They’re fiber‑based, widely recyclable where paper packaging is accepted, and designed to be biodegradable. Follow local guidelines.

Q3: Can I add my logo and brand color?

A: Absolutely—embossed/debossed logos and custom color matching are available for a premium, ink‑free look.

Q4: Are they suitable for direct food/egg contact?

A: Yes, molded pulp egg cartons are commonly used for direct contact. For specific regional certifications, request documentation.

Q5: What is the MOQ and can I order samples?

A: MOQ is 5,000 pcs. Samples are available; lead time depends on tooling and order size. Contact us for a fast quote and schedule.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Industrial packaging has entered a new era. For decades, heavy machine parts, precision components, and

The global packaging industry is changing faster than it has in decades. Businesses that once

What “energy-saving” means and what it doesn’t When suppliers say “energy-saving household paper machine,” they