Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

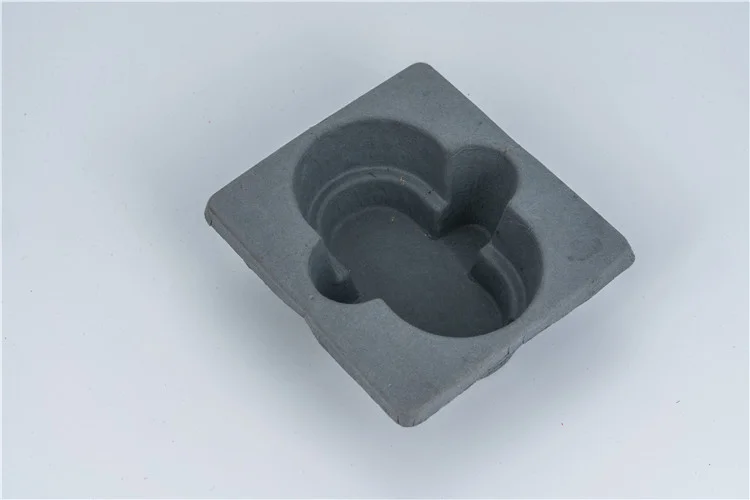

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

We start with sugarcane bagasse and bamboo fibers—renewable byproducts—and form each container using wet‑press molding. The process densifies the material, producing crisp edges, stable hinges, and a smooth, matte finish that feels premium in hand. The 3‑compartment layout keeps proteins, sides, and sauces neatly separated so fries stay crisp and greens stay fresh. A reinforced rim helps the lid close cleanly and stack securely, and optional venting lets steam escape to maintain texture on hot items.

Customization is your edge. Share SKU dimensions and we’ll dial in the footprint, wall height, hinge geometry, and compartment sizes; add label flats for branding or nutrition info, and choose a natural or bleached look with embossed/debossed logos for an ink‑free, upscale finish. Standard clamshells handle typical grease and moisture; for extra‑oily recipes or long delivery routes, specify an oil/moisture barrier to keep boxes crisp.

Operationally, these containers ship nested to reduce pallet height and storage footprint, and their repeatable fit speeds pack‑outs and reduces rework. End‑of‑life guidance remains honest: the body is fiber‑based and designed to be compostable (often in industrial/municipal facilities; check local programs). Food‑soiled items may not be recyclable—follow regional guidelines. With OEM/ODM support and an MOQ of 5,000 units, you’ll prototype quickly, scale confidently, and serve every order in packaging that protects quality and your sustainability goals.

FAQs:

Q1: Is it microwaveable and food‑safe?

A: Yes—suitable for typical hot/cold foods and short microwave reheats. Food‑contact documentation is available upon request.

Q2: How well does it handle grease and sauces?

A: It resists typical grease and moisture. For very oily or long‑haul delivery, choose an optional oil/moisture barrier.

Q3: Can I customize compartments, vents, and branding?

A: Absolutely—footprint, compartment sizes, venting, and embossed/debossed logos can all be tailored to your menu and brand.

Q4: Is it compostable or recyclable?

A: It’s fiber‑based and designed to be compostable under proper conditions. Recycling of food‑soiled items varies by region—check local rules.

Q5: What are the MOQ and lead times? Are samples available?

A: MOQ is 5,000 pcs. Samples can be arranged; production timing depends on customization and quantity. Request a fast quote for schedules.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Introduction: Why Bagasse Manufacturing Is No Longer Optional The shift toward compostable food packaging is

Introduction: Why Rotary Systems Dominate High-Volume Manufacturing In industrial manufacturing, speed alone does not create

Introduction: The Rise of Home-Based Plastic Manufacturing The idea of owning a plastic injection molding