Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

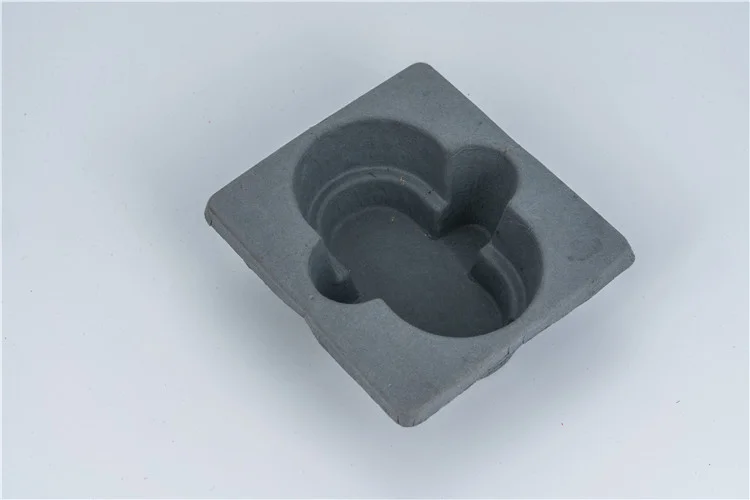

Eyelashes are fragile, and their packaging needs to safeguard them against bending, crushing, or tangling. Custom pulp packaging interior trays for eyelashes beauty are designed with precision to hold each lash set securely in place, ensuring they arrive in pristine condition every time.

Presentation matters, especially in the beauty industry. These pulp trays not only protect the lashes but also display them beautifully. The clean lines and tailored design give an elegant and professional touch that appeals to customers and elevates the unboxing experience.

Sustainability is at the forefront of modern packaging solutions. Made from biodegradable or recyclable materials, these pulp trays help reduce waste and meet the growing demand for eco-conscious products. Your brand can stand out as an advocate for the environment while delivering high-quality packaging.

Every brand is unique, and packaging should reflect that. These pulp trays can be customized in shape, size, and design to fit your specific requirements. Whether you prefer minimalistic packaging or bold, branded visuals, these trays can bring your vision to life seamlessly.

Shipping costs can add up, especially for lightweight beauty products. Pulp packaging interior trays are not only durable but also lightweight, keeping shipping expenses low without compromising on protection or quality.

Why It’s the Perfect Solution for Your Brand

From protecting delicate lashes to showcasing them in style, custom pulp packaging interior trays for eyelashes beauty tick all the boxes. They’re environmentally friendly, cost-efficient, and fully customizable, making them the ultimate packaging choice for any beauty brand.

Ready to Elevate Your Packaging Game?

Your eyelashes deserve packaging that’s as flawless as the lashes themselves. So, what’s stopping you from upgrading to custom pulp trays? Let’s create packaging that protects, impresses, and reflects your commitment to quality!

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Introduction: Why Home Plastic Injection Molding Is Becoming Popular Plastic injection molding has long been

Introduction: Why Wood Pulp Machinery Is Critical for the Industry For businesses involved in paper

Introduction: Why the Shift Away from Plastic Matters For decades, coffee machines have relied on