Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

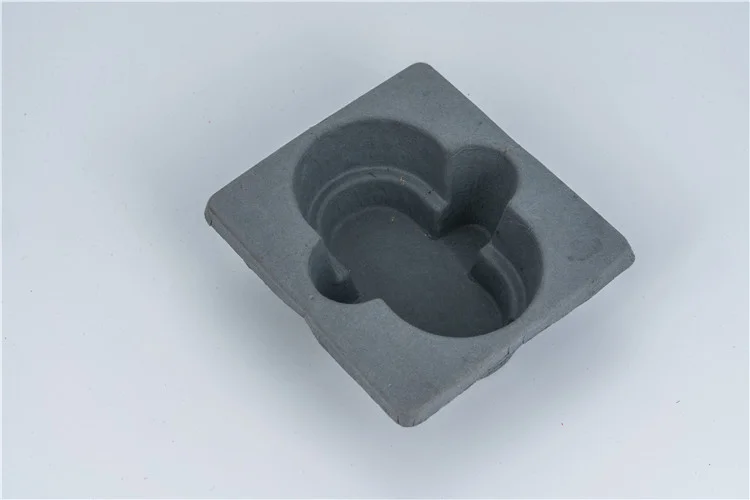

This molded pulp paint tray is built on a simple idea: better materials make better tools—and a better future. Starting with recycled paper board, the tray is formed through a chemical‑free pulping process, resulting in a non‑chemically modified product that’s tough, dependable, and kinder to the environment. The water‑resistant finish helps the tray hold its shape and function throughout typical painting tasks, providing a confident alternative to plastic without the guilt of long‑term landfill impact.

From there, it’s all about fit and flexibility. Need a specific shape, deeper well, or a brand‑matched color? We can customize dimensions, geometry, and color, and add your logo so your brand is front and center on every project. Custom packaging is available too, making it retail‑ready or optimized for bulk distribution. The tray’s molded pulp texture offers a naturally grippy feel, and its nestable form packs tight to reduce storage space and shipping volume.

End of life matters, too. The tray is 100% biodegradable and compostable under proper conditions. If trays are heavily soiled with paint, follow local guidelines—industrial composting or proper disposal may be required. For cleaner pieces, recycling may be possible where facilities accept fiber products. With an MOQ of 5,000 units and scalable production, this molded pulp paint tray gives you a reliable, eco‑smart solution that stands out from plastic—and stands up to real work.

FAQs:

Q1: Is this tray fully biodegradable and compostable?

A: Yes—it’s 100% biodegradable and compostable under proper conditions. Follow local guidelines, especially if trays are heavily soiled with paint.

Q2: Will it hold up during painting?

A: The tray is water‑resistant and designed for reliable performance in typical painting sessions. Avoid prolonged soaking or harsh solvents.

Q3: Can I customize size, shape, color, and add my logo?

A: Absolutely. We offer custom shapes, sizes, colors, and logo printing to match your brand and application.

Q4: What is the minimum order quantity (MOQ)?

A: The MOQ is 5,000 pieces. Bulk pricing and custom packaging are available.

Q5: Do you offer samples and what about delivery?

A: Samples can be arranged upon request. Lead times and shipping depend on quantity and customization—contact us for a precise quote and schedule.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Industrial packaging has entered a new era. For decades, heavy machine parts, precision components, and

The global packaging industry is changing faster than it has in decades. Businesses that once

What “energy-saving” means and what it doesn’t When suppliers say “energy-saving household paper machine,” they