Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

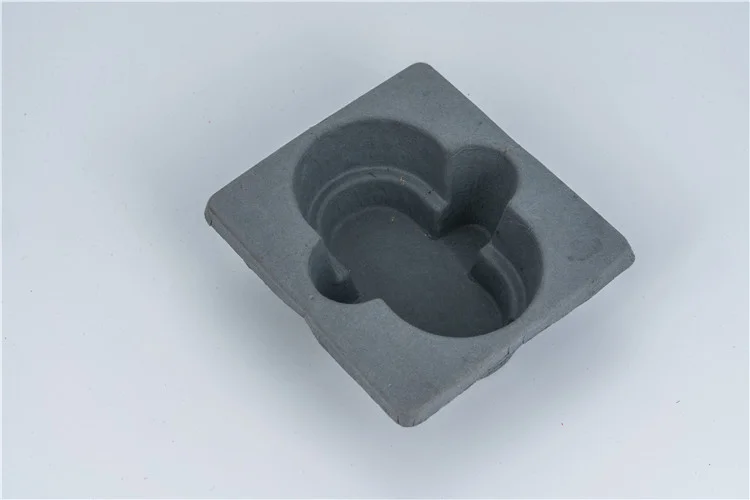

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

Great shipping boxes should protect in transit, look polished on arrival, and work seamlessly on your line. Our recycled corrugated mailers are precision die‑cut for crisp folds, reliable locks, and clean edges that hold shape under load. The result: cartons that stack neatly in your warehouse, assemble in seconds without excess tape, and keep products secure from pick line to unboxing. Your brand gets center stage with robust customization—choose exact dimensions, specify folder/slotted styles, and select finishes that match your aesthetic. Offset or spot color printing, UV coating for abrasion resistance, and embossed/debossed logos deliver a premium, tactile feel. Inside, add paperboard inserts to separate items and reduce movement; outside, color‑match to your palette for a cohesive story.

Sustainability is built in. Using recycled, fiber‑based materials makes end‑of‑life simple for customers and supports your eco goals. Because mailers ship flat and nest efficiently, you’ll cut inbound freight and storage footprint—key wins when volumes spike. Want a luxe touch? Integrate an optional magnetic closure, or keep it single‑material for easier recycling. With OEM/ODM support and an MOQ of 5,000 pcs, we’ll help you prototype fast and scale confidently—so every order arrives protected, on‑brand, and ready to impress.

FAQs:

Q1: Can I customize size, style, and printing?

A: Yes. We tailor dielines and dimensions, and offer emboss/deboss logos, UV coating, and custom colors to match your brand.

Q2: Do the boxes ship flat and assemble easily?

A: They arrive flat for efficient storage and fold together quickly—ideal for fast pack‑outs with minimal or no tape.

Q3: Are these mailers recyclable and eco‑friendly?

A: Yes. They’re fiber‑based with recycled content and widely recyclable where paper packaging is accepted. Check local guidelines.

Q4: Can you add inserts or magnetic closures?

A: Absolutely. We offer paperboard inserts/liners and optional magnetic closures for a premium reveal.

Q5: What are the MOQ and lead times? Are samples available?

A: MOQ is 5,000 pcs. Samples are available on request; lead time depends on size, finishes, and quantity—contact us for a fast quote.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Introduction: Why Bagasse Manufacturing Is No Longer Optional The shift toward compostable food packaging is

Introduction: Why Rotary Systems Dominate High-Volume Manufacturing In industrial manufacturing, speed alone does not create

Introduction: The Rise of Home-Based Plastic Manufacturing The idea of owning a plastic injection molding