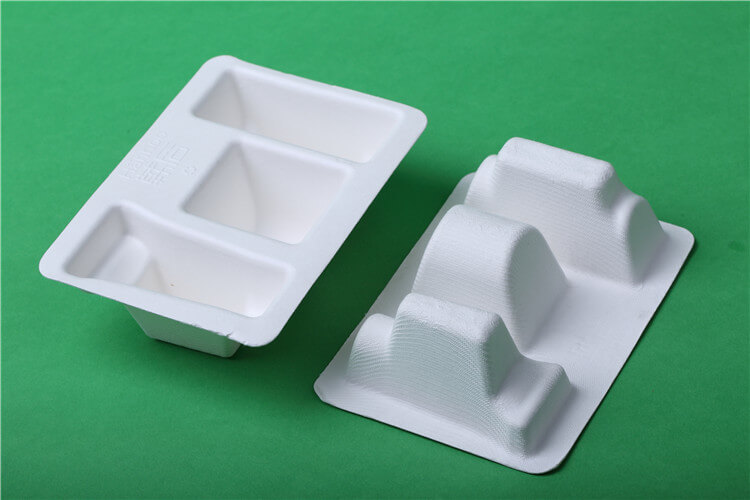

Despite being lightweight, these trays are incredibly durable. The wet pressing process strengthens the material, offering excellent protection against impacts. This durability ensures that your cosmetic products arrive in perfect condition, enhancing customer satisfaction.

- Cost-Effective and Versatile

Switching to sustainable packaging doesn’t have to break the bank. These trays are competitively priced and can be customized to fit various cosmetic product sizes and shapes. Their versatility makes them a cost-effective choice for brands of all sizes.