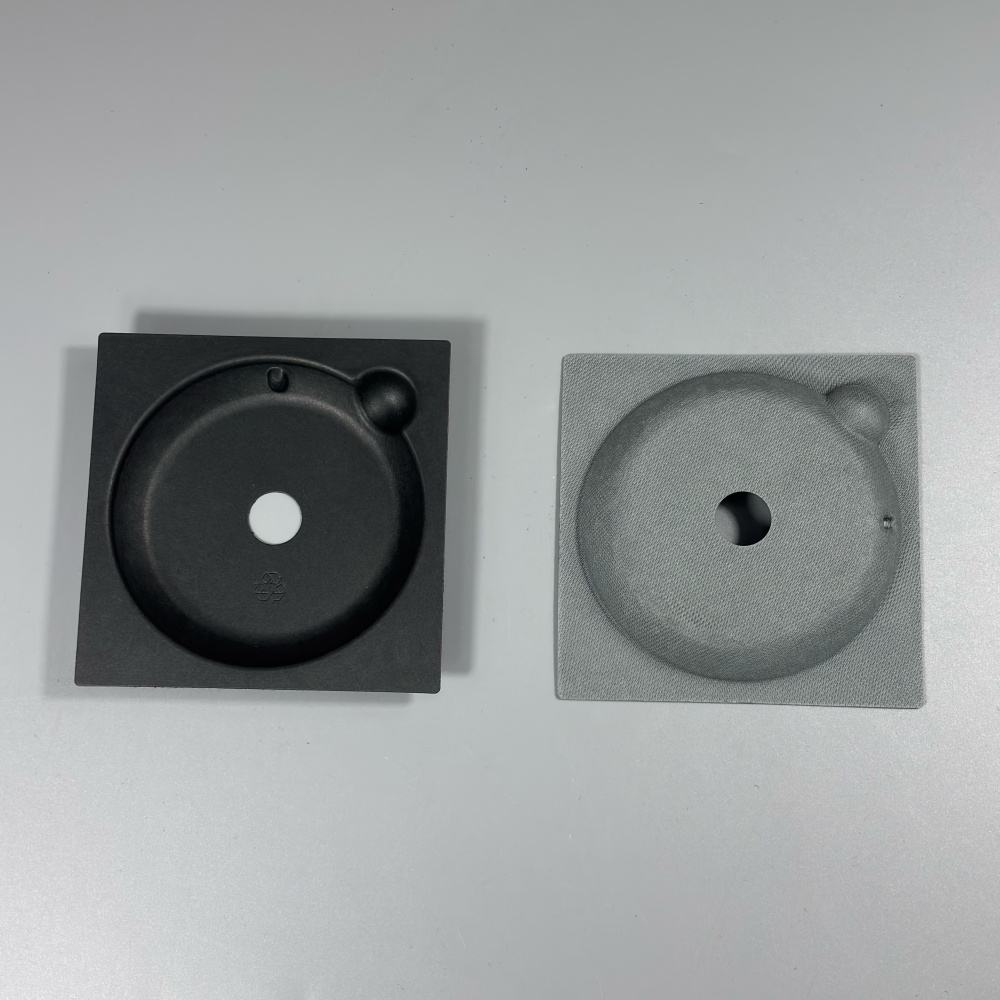

Molded pulp has evolved into a high‑performance, low‑impact alternative to foam and plastic. Our wet‑press process compresses plant fibers into dense, dimensionally stable parts with consistent wall thickness and soft radii that won’t scratch glass or printed labels. Share CAD files or sample bottles and our engineers will map exact clearances for the base and shoulders, tune well depth to prevent wobble, and integrate details like finger‑pull notches, tie slots, or the center hole for base alignment or fast de‑nesting. We’ll size the flange for a snug drop‑in fit to slotted cartons or rigid gift boxes—often without adhesives—to speed pack‑out and keep presentations pristine.

Operational wins are immediate: trays nest tightly to maximize pallet density, weigh less than plastic to lower emissions and freight, and arrive production‑ready with repeatable tolerances that keep your line moving. Branding is built in—emboss or deboss your logo directly into the fiber—and the pulp can be color‑tinted for seasonal releases. After unboxing, consumers can recycle the insert where molded fiber is accepted or compost it in suitable facilities, giving your brand a credible sustainability story alongside robust protection.

FAQs:

Q1: Are these trays recyclable and compostable?

A: Yes. They’re made from plant‑based molded fiber, recyclable in many paper streams and compostable where facilities exist.

Q2: Can you match my bottle size and add a base lock?

A: Absolutely. We create custom tooling for your bottle dimensions and can add a center base/punt lock, anti‑roll stops, or finger‑pulls.

Q3: Do you offer moisture resistance?

A: Standard trays are uncoated. Optional water‑repellent or oil‑resistant finishes are available for humid supply chains.

Q4: What colors and branding options are available?

A: Natural white, black, gray, or custom tints. Embossed/debossed logos provide elegant, ink‑free branding.

Q5: What are the MOQ and lead times?

A: MOQ is 5,000 units. Sampling typically takes 7–10 days after design approval; production is usually 15–30 business days.