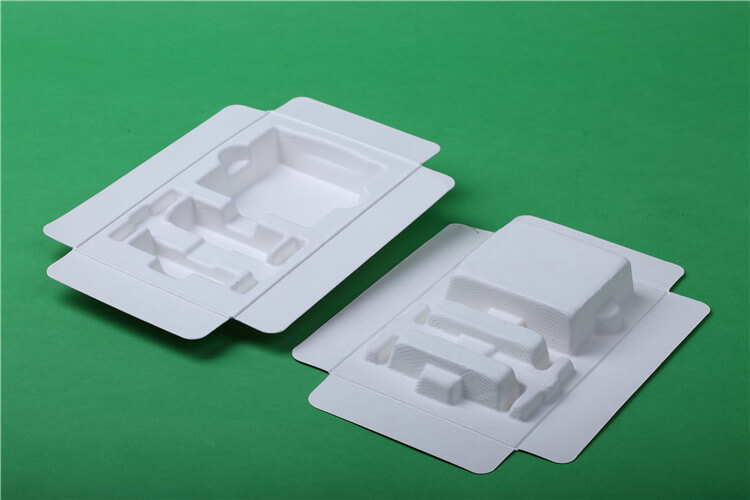

The model number BNT-EC001 is made from sugarcane fiber (bagasse) and comes in white (bleached) color. It measures 35204.5cm with an embossed logo. Packing options include stacked, poly bag, and export carton, with pallets available. The minimum order quantity (MOQ) is 5000 pieces per item. Sample mold and lead time are 7 days, with a sample mold lead time of 10 days. The production lead time is 15 days.

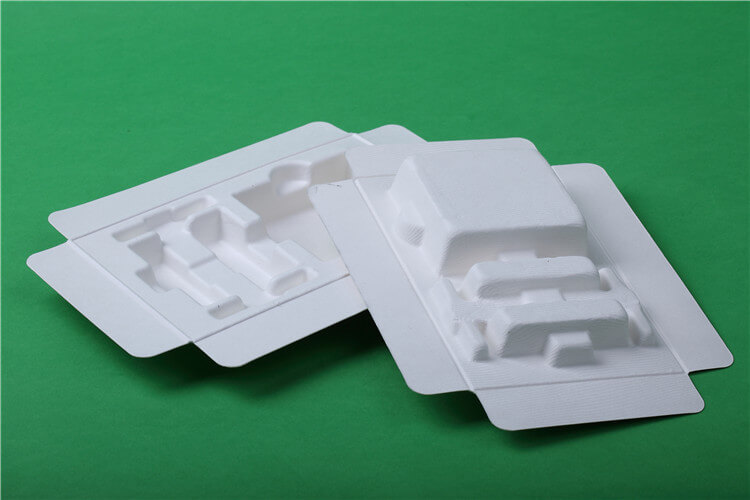

Wet Press Molded Fiber vs Dry Press Molded Fiber

| Description | Wet Press Molded Fiber | Dry Press Molded Fiber |

|---|---|---|

| Material | Sugarcane fiber, bamboo fiber | Corrugated pulp, wood pulp |

| Sustainability | Biodegradable & Compostable | Recyclable |

| Surface | One side smooth, another side with texture | Rough surface |

| Color | White, Natural, Black, Pantone Custom Color | Natural, Black, White |

| Price | Stable | Variable |

| Thickness | 0.7 ~ 1.2mm | 1.5 ~ 3.0mm |

| Drop testing | Good | Great |

| Cushioning | Great vibration & cushioning | Good vibration & cushioning |

| Protection | Geometry | Geometry |

| Shipping & Storage | Stackable, small packing space | Stackable, large packing space |

| Static | Static neutral | Static neutral |