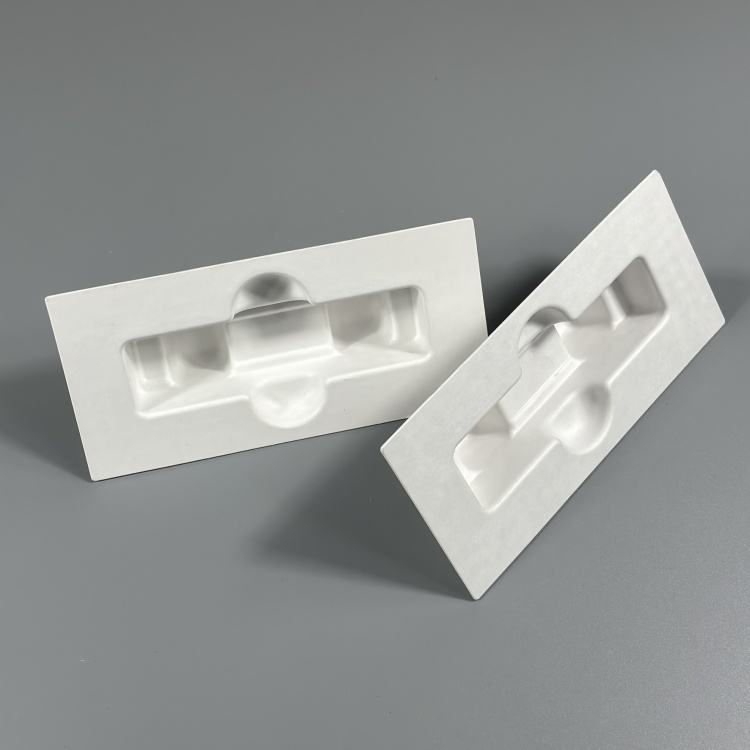

What Makes Our Trays Special? Your own mini tech savior that keeps everything tidy and protected! Our trays are like a cozy bed for your devices, with soft packaging that hugs your devices and keeps them damage-free.

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

Foam flakes and vac‑form creaks don’t say “premium.” Wet‑pressed molded pulp turns plant fiber into dense, durable protection with consistent wall thickness and smooth radii that cradle ear cups and headbands without pressure points. Start by sharing CAD files or a sample set—our engineers map clearances for hinges, sliders, and mics; add cable channels; and build accessory wells sized to your kit. We can deliver an insert that drops into your current carton or a full clamshell that locks product in place for display.

Operational advantages stack up fast. Pulp trays nest tightly, maximizing pallet density and minimizing warehouse space. They’re lighter than plastic, lowering transport emissions and costs, and they arrive production‑ready with repeatable tolerances for fast pack‑out. Branding integrates seamlessly—emboss or deboss your logo directly into the fiber for an elegant, scratch‑proof mark—and the pulp can be tinted to your signature color. After the reveal, customers can recycle the insert where molded fiber is accepted, or it will biodegrade in suitable conditions—an authentic sustainability story that resonates with audio buyers. With superior cushioning, a refined tactile feel, and real environmental benefits, this molded pulp headphone tray is the modern standard for premium audio packaging.

FAQs:

Q1: Can you fit my specific headphone model and accessories?

A: Yes. We create custom tooling from your CAD or samples, including pockets for cables, dongles, and manuals.

Q2: Is the tray recyclable and biodegradable?

A: It’s plant‑based, plastic‑free molded fiber—recyclable in many paper streams and naturally biodegradable; check local guidelines.

Q3: Insert tray or clamshell—what’s best?

A: Inserts are ideal for boxed sets; clamshells add retail protection and display. We can design either to your box size.

Q4: What branding and color options do you offer?

A: Embossed/debossed logos are standard. Choose natural kraft, white, or a custom‑tinted color to match your brand.

Q5: What are the MOQ and typical lead time?

A: MOQ is 5,000 units. Samples usually take 7–10 days after approval; mass production typically 15–30 business days.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Introduction: The Technology Behind Paper Water Bottle Production As sustainability regulations tighten and consumers demand

Introduction: Why Choose Coffee Machines with No Plastic? The shift toward eco-friendly coffee machines has

Introduction: Why Molded Pulp Tooling Is the Foundation of Sustainable Packaging As global industries shift