What if your cosmetic packaging could do more than just ‘hold the product’?

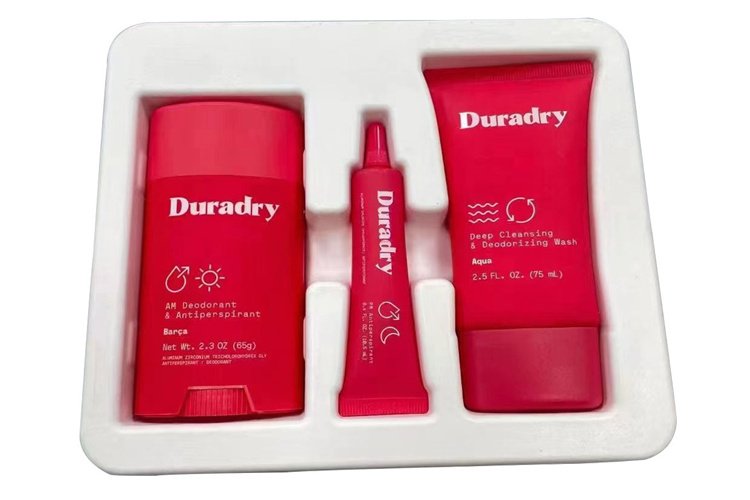

Think about this: Your precious serums, delicate powders, and luxurious creams, all nestled safely in custom-fitted spaces. No more customer complaints about broken bottles or spilled products. Our Trays for Cosmetic & Beauty Products don’t just hold your items – they protect your brand’s reputation with every shipment.

Want to know the best part of our Trays for Cosmetic & Beauty Products? These trays work perfectly with standard shipping boxes, making your entire fulfillment process smoother than ever. When your beauty products look their best, your brand shines. Give your customers packaging that feels as good as it looks and keep those 5-star reviews rolling in!

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

Design & customization for every soap style

The BonitoPak PM‑126 pulp soapbox is engineered to fit your bar perfectly—whether you produce classic oval bars, square artisan cuts, shampoo bars or facial cleansing bars. We design the inner profile to cradle the soap gently, preventing abrasion while allowing easy pick‑up with curved finger notches. Choose a two‑piece base and lid set or an integrated hinged style with snap tabs for quick packing on the line. Venting is customizable: add discreet holes, channels or a removable fiber drain pad to elevate the bar and allow airflow. This helps soaps dry faster between uses and arrive firm after long transit.

Materials that respect skin and planet

Made from recycled paper and agricultural fibers, the soapbox contains no plastic laminations, foaming agents or harsh chemicals. The surface is smooth to the touch—ideal for premium bath and body brands—and remains fully recyclable in paper streams. For brands aiming at zero‑waste goals, the box is home‑compostable in suitable conditions, returning to nature without leaving residues. Water‑based pigments allow Pantone color matching while maintaining recyclability.

Retail presence with a natural look

Emboss your brand name, scent icons, or usage illustrations directly into the lid for a premium, minimalist appearance without extra labels. Pair the pulp box with a paper belly band or sleeve for storytelling and ingredients. The rigid geometry protects the bar during handling and resists compression in e‑commerce. Because the halves nest tightly, shipping volume is minimized, lowering logistics cost and emissions.

Production, quality & lead time

We start from your bar dimensions or CAD. After a quick DFM review, we build polished tooling to achieve clean edges and consistent fit. Typical tolerance is ±0.5 mm. Sample molds and first articles are delivered in about 10 days, with mass production usually 15–25 days after approval. MOQ is 5000 pieces per design/color. We provide export‑ready packing and can coordinate EXW/FOB/CIF shipping terms.

Use cases beyond the bath

The pulp soapbox also works as a compact, plastic‑free case for solid shampoos, conditioner bars, travel kits, hotel amenities, or eco gift sets. With a removable liner, it can hold cotton pads or small skincare items, helping you create a cohesive family of sustainable personal‑care packages.

Q1: Is the soapbox safe for direct contact with cosmetic products?

A: Yes. It is made from paper pulp with no plastic film or added chemicals. Food‑ or cosmetic‑contact options are available upon request.

Q2: Will the soap stick to the box?

A: We design drainage and airflow features—holes, channels or a fiber pad—to keep the bar dry and reduce sticking.

Q3: Can I add my logo to the lid?

A: Absolutely. We support embossed/debossed logos and can tint the pulp to your Pantone color.

Q4: What sizes can you make?

A: Fully custom. Send your bar dimensions and we will tailor the cavity and structure to fit.

Q5: How durable is the box for shipping?

A: The wet‑press structure is rigid and stack‑strong. We can add ribs or thicker walls for e‑commerce and long‑haul routes.

Q6: What is the minimum order and lead time?

A: MOQ 5000 pcs. Samples in about 10 days; mass production 15–25 days after approval.

Ready to create a plastic‑free soap package?

Share bar size, color, logo and order quantity. We’ll design your compostable soapbox, sample fast and deliver on time with BonitoPak PM‑126.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

When looking to boost efficiency in paper production, finding the right machine can be a

In the pulp and paper industry, selecting the right machinery can drastically impact your production

Are you concerned about the harmful chemicals lurking in your coffee machine? If you’re a