Home » Services » Wet pressing Molded Pulp Trays » Page 9

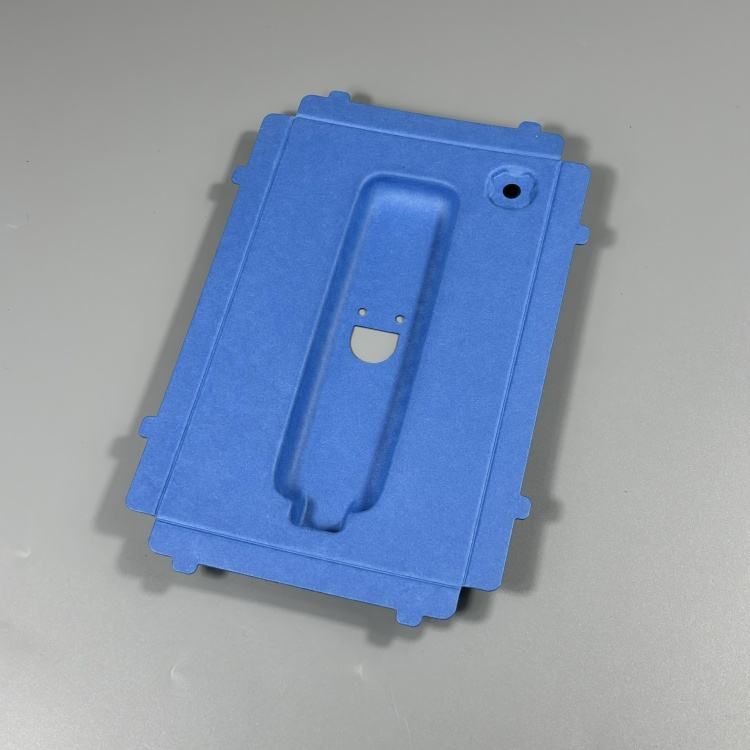

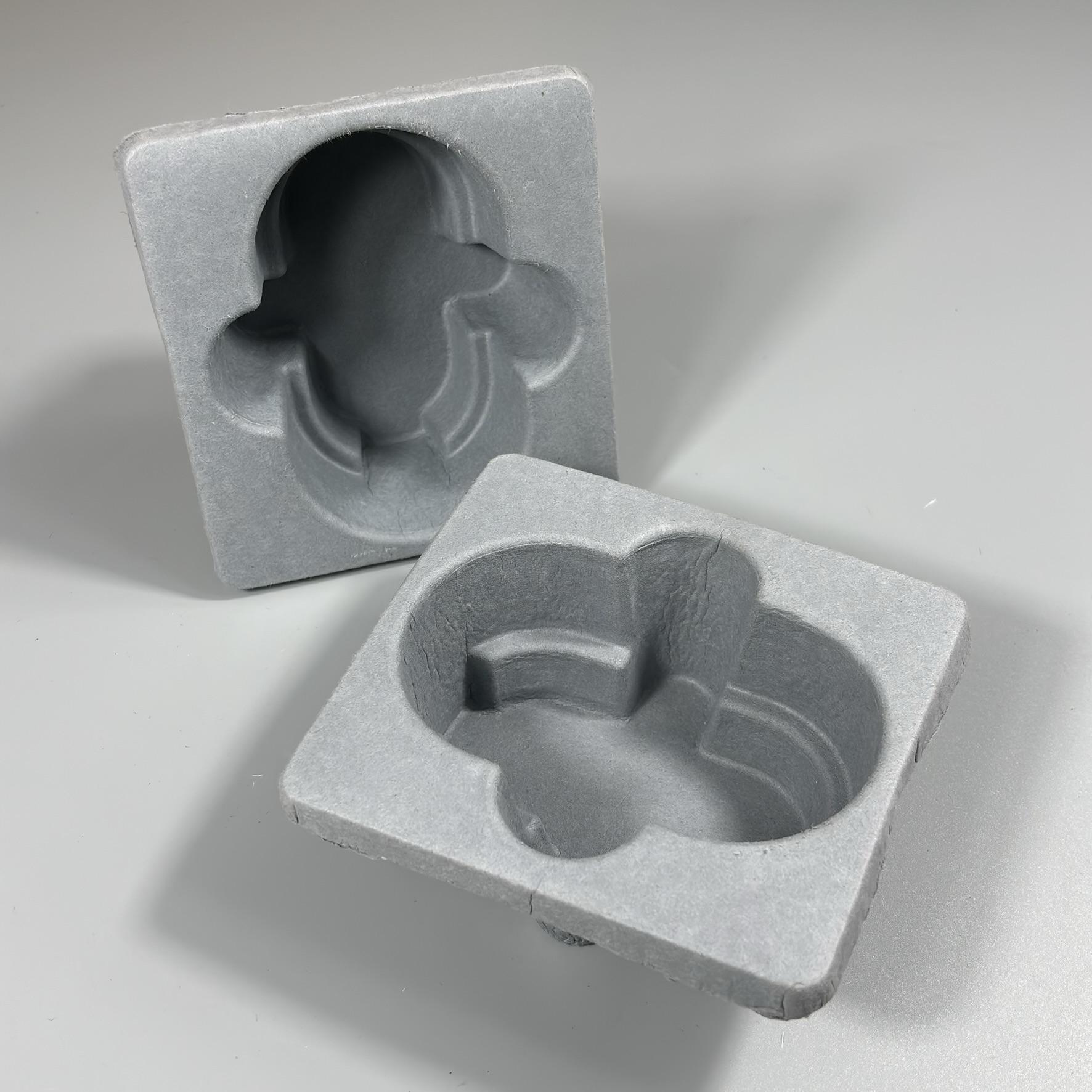

Wet pressing process is a new type of modern technology, which is widely used in insert &inner tray packaging options. Molded pulp products made from 100% biodegradable & compostable material, sugarcane fiber (as known as bagasse), bamboo fiber, wood pulp, recycled paper pulp and other natural plant fiber.

The products not only with very smooth surface and finish that enhance your brand values, but superior packaging performance, protection, cushioning, nesting and stacking capabilities, saving space, assemble and transports cost.

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

Design & customization

Performance & protection

Sustainability & materials

Sampling, quality & lead time

Packing & delivery

Side‑by‑side services

Q1: Can one tray support multiple dryer models?

A: We can create a common outer size with interchangeable inserts for model‑specific bodies and nozzles to keep your carton the same.

Q2: Can you add a water‑resistant finish?

A: Yes. Optional water‑based coating or paper liner is available for humid routes while keeping recyclability.

Q3: Will the pulp scratch glossy housings?

A: No. We design soft radii and use a smooth wet‑press face; samples are provided for validation.

Q4: What thickness is recommended?

A: 0.8–1.6 mm is typical for hair dryers. We tune thickness and ribs to weight, drop tests and carton style.

Q5: What information do you need to start?

A: Device dimensions/CAD, accessories list, carton size, color/branding, target quantity and timeline.

Q6: What is the MOQ and lead time?

A: MOQ 5000 pcs. Sampling about 10 days; production 15–25 days after approval.

Ready to design a plastic‑free hair‑dryer insert?

Share your sizes, layout and brand color. We’ll design the cavity, sample fast and deliver on time with BonitoPak PM‑039.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Industrial packaging has entered a new era. For decades, heavy machine parts, precision components, and

The global packaging industry is changing faster than it has in decades. Businesses that once

What “energy-saving” means and what it doesn’t When suppliers say “energy-saving household paper machine,” they