Home » Services » Wet pressing Molded Pulp Trays » Page 6

Wet pressing process is a new type of modern technology, which is widely used in insert &inner tray packaging options. Molded pulp products made from 100% biodegradable & compostable material, sugarcane fiber (as known as bagasse), bamboo fiber, wood pulp, recycled paper pulp and other natural plant fiber.

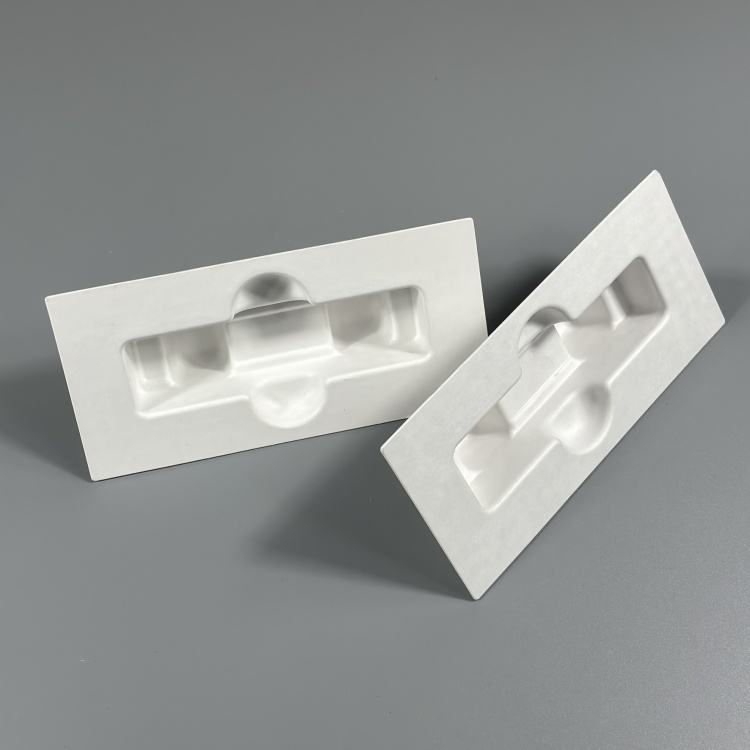

The products not only with very smooth surface and finish that enhance your brand values, but superior packaging performance, protection, cushioning, nesting and stacking capabilities, saving space, assemble and transports cost.

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

Molded pulp has grown up. Our wet‑press process compresses sugarcane bagasse and recycled fibers under heat to create dense walls with consistent thickness and refined radii that protect delicate glass while feeling luxurious in hand. Share CAD files or a sample set and our engineers will build precision tooling for your architecture: bottle diameters, shoulder profiles, and finger‑pulls for easy removal. Need an insert that stays put? We can tune flange size for slotted boxes or add locking features for rigid cartons.

Operational wins follow quickly. Trays nest tightly to maximize pallet density, are lighter than plastic to reduce transport emissions, and arrive production‑ready with dependable tolerances that speed packing. Branding integrates seamlessly—emboss or deboss your logo directly into the fiber—and the pulp can be tinted to match seasonal collections. After the reveal, customers can recycle the tray where molded fiber is accepted, or it will biodegrade in suitable conditions, reinforcing your clean‑beauty values. From DTC gift sets to prestige retail, this bagasse pulp tray delivers premium protection, a modern unboxing moment, and a credible sustainability story.

FAQs:

Q1: Can you match my serum/ampoule sizes exactly?

A: Yes. We create custom tooling from your CAD or samples for precise, rattle‑free cavities and easy lift‑outs.

Q2: Is the tray recyclable and biodegradable?

A: It’s plastic‑free, made from bagasse/recycled fibers, recyclable where accepted, and naturally biodegradable.

Q3: What branding and color options are available?

A: Embossed/debossed logos are standard. We can tint the pulp to your brand color or seasonal palette.

Q4: What are the MOQ and lead times?

A: MOQ is 5,000 units. Sampling typically takes 7–10 days after approval; production is usually 15–30 business days.

Q5: Do you offer moisture or oil resistance?

A: Yes. Optional water‑repellent/oil‑resistant treatments are available for humid supply chains or oil‑rich formulas.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Industrial packaging has entered a new era. For decades, heavy machine parts, precision components, and

The global packaging industry is changing faster than it has in decades. Businesses that once

What “energy-saving” means and what it doesn’t When suppliers say “energy-saving household paper machine,” they