Home » Services » Wet pressing Molded Pulp Trays » Page 4

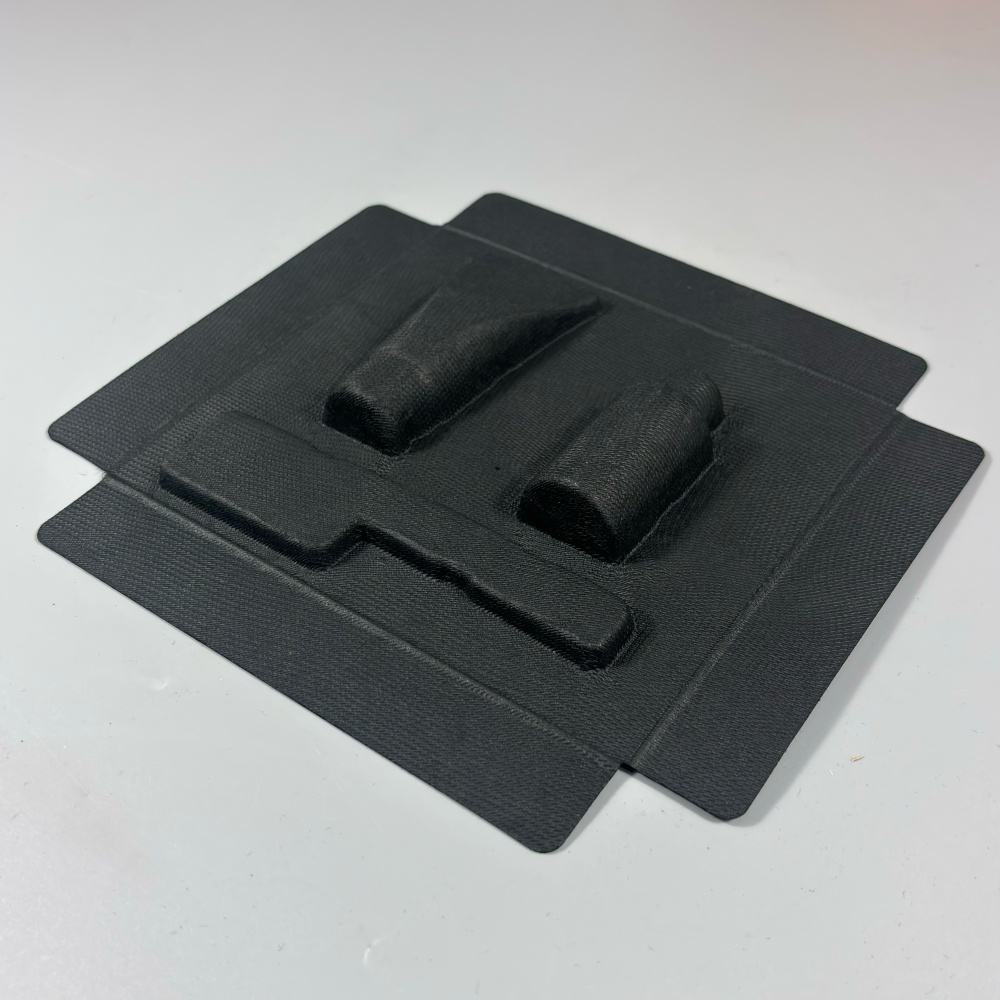

Wet pressing process is a new type of modern technology, which is widely used in insert &inner tray packaging options. Molded pulp products made from 100% biodegradable & compostable material, sugarcane fiber (as known as bagasse), bamboo fiber, wood pulp, recycled paper pulp and other natural plant fiber.

The products not only with very smooth surface and finish that enhance your brand values, but superior packaging performance, protection, cushioning, nesting and stacking capabilities, saving space, assemble and transports cost.

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

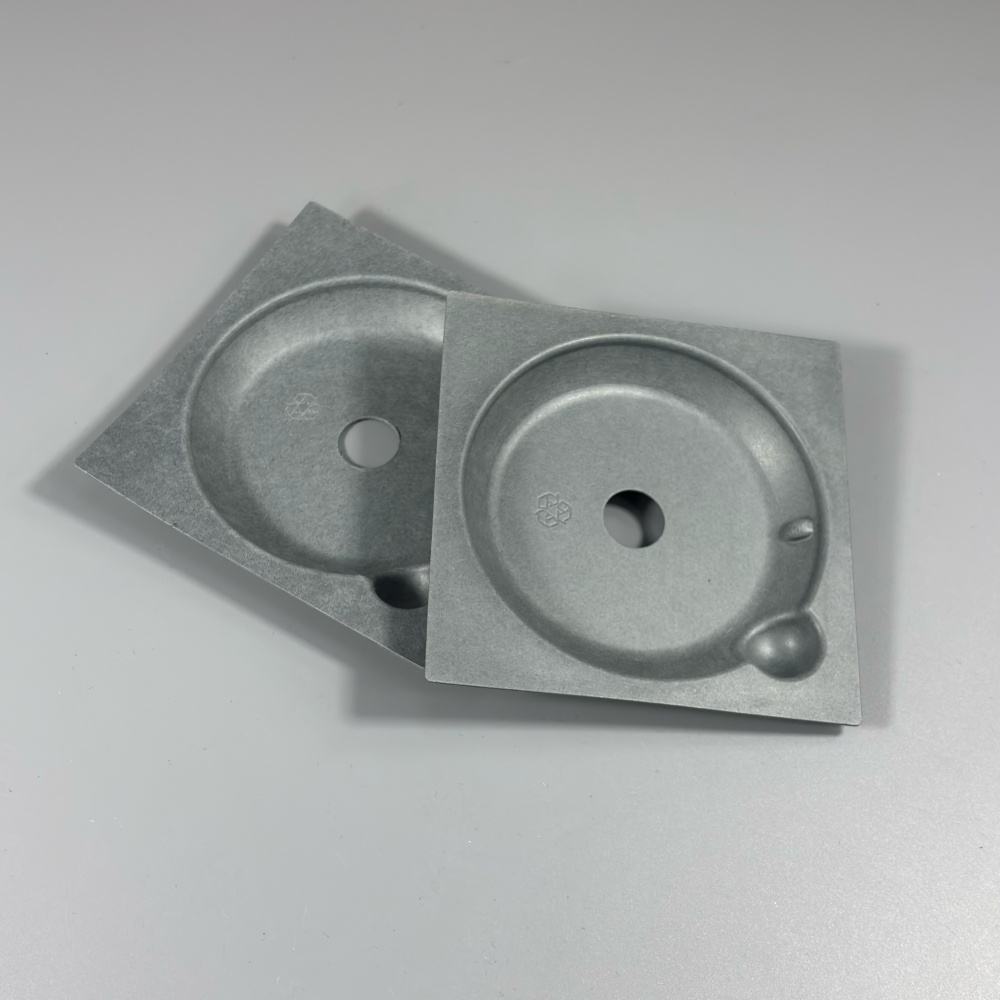

When glass breaks, brands pay. This molded pulp wine tray solves that with engineered, fiber‑based protection that’s as thoughtful as it is tough. We start with recycled paper pulp and form it using wet‑pressed tooling that produces crisp edges, consistent tolerances, and a smooth, premium surface. The result: a molded pulp wine tray that holds bottles firmly in place, dampens vibration, and resists crush during transport and warehousing.

Customization is our superpower. Whether you need single‑bottle gift packs, two‑ or three‑count sets, or six‑ and twelve‑pack shipping inserts, we’ll dial in cavity geometry for your exact bottle profile. Add neck locks, base cushions, or accessory wells for corkscrews and cards. Finish with an embossed logo and a brand‑right color to turn protection into presentation.

Operationally, it’s built to make life easier. Trays are lightweight and nestable, reducing pallet height and freight spend. They drop into standard slotted boxes with optional paperboard liners for a fully fiber‑based system. And because the pulp is made from recycled materials via a chemical‑free pulping process, you’re shifting away from plastics and foams to packaging that’s recyclable and easier to explain to eco‑conscious customers.

From DTC shipments to wholesale pallets, this pulp packaging for wine bottles delivers lower breakage, a cleaner aesthetic, and a clear sustainability win—without complicating your line.

FAQs:

Q1: Can you match my exact bottle size and configuration?

A: Yes. We customize cavity diameter/height, neck support, and pack counts (1/2/3/6/12). Share specs or samples for a perfect fit.

Q2: What branding options are available?

A: Embossed logos are standard; custom colors are supported. We can advise on placements that remain legible after molding.

Q3: Are the trays recyclable and eco‑friendly?

A: They’re made from recycled paper pulp and are widely recyclable where fiber packaging is accepted. Always follow local recycling guidance.

Q4: Will these work with my existing cartons?

A: Typically yes. They’re designed for slotted boxes and can pair with paperboard liners. We can size trays to your current cartons.

Q5: What are the MOQ and lead times? Can I get samples?

A: MOQ is 5,000 pieces. Samples are available; lead time depends on tooling and order size—contact us for a fast quote and schedule.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Introduction: Why Home Plastic Injection Molding Is Becoming Popular Plastic injection molding has long been

Introduction: Why Wood Pulp Machinery Is Critical for the Industry For businesses involved in paper

Introduction: Why the Shift Away from Plastic Matters For decades, coffee machines have relied on