Home » Services » Dry Pressing Molded Pulp Trays » Page 2

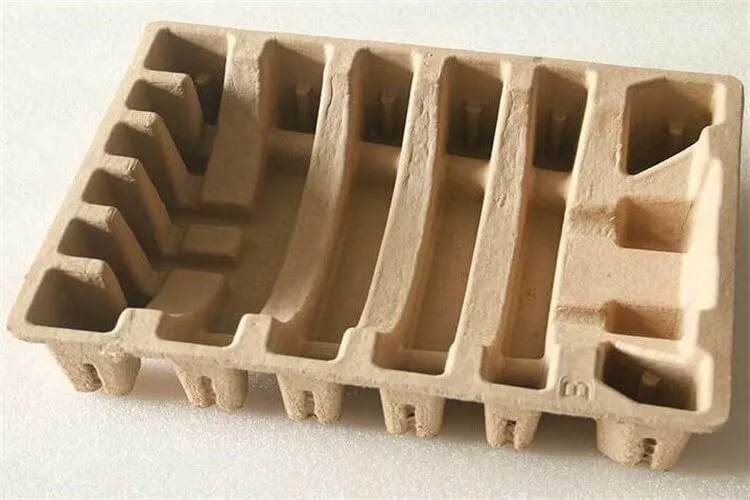

Dry pressing paper pulp tray made from abundantly available 100% recycled corrugated, recycled paper material. Molded pulp cost less expensive, eco-friendly alternative that compared to EVA, cardboard, corrugated, vacuum formed PET, PS , and other plastic products.

With these trays, you’re not just packing a product—you’re sending a message of reliability, care, and commitment. So, what’s the best part of our dry pressing molded pulp trays, and what’s leaving you craving to buy one?

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

Material :

The wet pressing process uses biodegradable materials like bagasse, bamboo, and recycled paper, offering smooth finishes, protection, cushioning, and space-saving, eco-friendly packaging.

Molded pulp products replace plastic and foam, offering recyclable, biodegradable options. Custom shapes, colors, and eco-friendly surfaces are available. We provide affordable, sustainable packaging with in-house prototyping and manufacturing.

Our plant fiber tableware, made from bagasse, straw, and bamboo, is biodegradable, compostable, waterproof, oil-resistant, and microwave-safe. Certified, recyclable, and stackable for eco-friendly use.

Dry pressing paper pulp trays, made from 100% recycled materials, offer an eco-friendly, cost-effective alternative to plastic. They provide cushioning, temperature resistance, and stackability, saving up to 20% space.

Bonitopak offers molded pulp in six colors, including white, natural, and black, with 95% color accuracy. Eco-friendly methods ensure safe bleaching. Natural and white are best for food; others suit tray packaging.

We respond within 24 hours, offering fast, clear communication, tailored solutions, and efficient service to save time and costs.

Our in-house design, engineering, and manufacturing ensure rapid tooling, with samples ready in 7 days and production molds in 8 days.

Our skilled R&D engineers excel in designing, prototyping, and tooling, offering complete packaging solutions with blister, tin can, and printed boxes.

Trained staff conduct 100% inspections, random checks, and quality control, ensuring high standards, reducing rejects, and saving costs.

We provide reasonable order scheduling and coordinate with clients to resolve issues promptly, ensuring the best solutions.

Our experienced after-sales team ensures smooth communication, solving issues with replacements, shipping, and delivery, aiming for zero complaints.

Introduction: Why Bagasse Manufacturing Is No Longer Optional The shift toward compostable food packaging is

Introduction: Why Rotary Systems Dominate High-Volume Manufacturing In industrial manufacturing, speed alone does not create

Introduction: The Rise of Home-Based Plastic Manufacturing The idea of owning a plastic injection molding