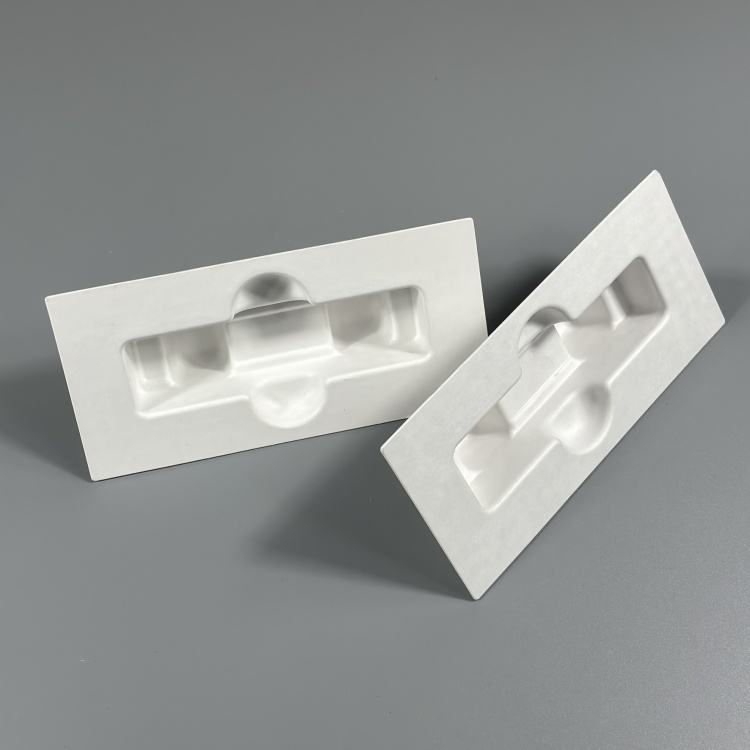

Modern tech buyers expect low‑impact packaging and a premium reveal. Our wet‑press process compresses recycled fibers under heat, creating dense walls with consistent thickness and smooth radii that won’t scratch housings or scuff printed manuals. Share CAD files or sample units and our engineers will map precise clearances, tune wall thickness, and design cable channels, charger wells, and accessory pockets tailored to your kit. We’ll size the flange for your existing slotted box so inserts lock in place without glue and load quickly on the line.

Operational benefits add up fast: trays nest tightly for high pallet density, weigh less than plastic to reduce shipping emissions, and arrive production‑ready with reliable tolerances. Branding integrates seamlessly—emboss or deboss your logo directly into the fiber for an elegant, ink‑free mark—and the pulp can be tinted to match your color story. After unboxing, consumers can recycle the insert where molded fiber is accepted, or it will biodegrade in suitable conditions. The result is a molded pulp electronics tray that protects in transit, streamlines packing, and tells a credible sustainability story that boosts brand perception.

Вопросы и ответы:

Q1: Can you match my device and accessory layout exactly?

A: Yes. We build custom tooling from your CAD or samples for precise, rattle‑free cavities and cable channels.

Q2: Is the insert recyclable and biodegradable?

A: It’s plastic‑free and made from recycled paper pulp—recyclable in many paper streams and naturally biodegradable.

Q3: Какие варианты брендинга доступны?

A: Embossed or debossed logos come standard; we can also color‑tint the pulp to your brand palette.

Q4: Каковы MOQ и типичное время выполнения заказа?

A: MOQ is 5,000 units. Sampling usually takes 7–10 days after design approval; production typically 15–30 business days.

Q5: Предлагаете ли вы влагостойкость?

A: Standard inserts are uncoated fiber. Optional water‑repellent/oil‑resistant treatments are available for humid supply chains.